News

Category

PTFE polytetrafluoroethylene

Publish:2023-12-09 14:00:04

PTFE polytetrafluoroethylene

English name: Polytetrafluoro ethylene

Specific gravity: 2.1-2.2 grams per cubic centimeter

Forming shrinkage rate: 3.1-7.7%

Forming temperature: 330-380 ℃

Drying conditions:---

Material performance

1. Long term use at temperatures ranging from -200 to 260 degrees Celsius, it has excellent chemical corrosion resistance and is resistant to all chemicals. Its friction coefficient is the lowest among plastics, and it also has excellent electrical properties. Its electrical insulation is not affected by temperature, earning it the title of "plastic king".

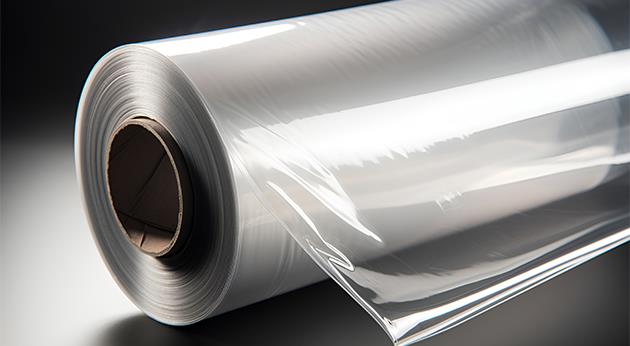

2. It is in a transparent or semi transparent state, and the higher the crystallinity, the worse the transparency. The raw materials are mostly powdered resins or concentrated dispersions, which have extremely high molecular weight and are high crystallinity thermoplastic polymers.

Suitable for making corrosion-resistant parts, wear reducing and wear-resistant parts, sealing parts, insulation parts, and medical device parts

Forming performance

1. Crystalline material with low moisture absorption.

2. Poor fluidity, easily decomposes, and produces corrosive gases during decomposition. It is advisable to strictly control the molding temperature, the mold should be heated, and the pouring system should have low resistance to material flow.

3. Powdered resins are often formed using powder metallurgy and sintering methods. The sintering temperature should be between 360 and 380 degrees, and should not exceed 475 degrees. Lotion resin is usually processed by cold extrusion and then sintering, which can form an anti-corrosion coating on the surface of articles. If transparency and good toughness are required for the product, rapid cooling should be adopted. Extrusion molding can also be adopted, which can extrude pipes, rods, and profiles.

4. The viscosity of PTFE melt is very high, and the volume viscosity decreases with the increase of shear stress, indicating its non Newtonian fluid characteristics.

5. Secondary processing can include hot pressing composite, welding, bonding, reinforcement, mechanical processing, etc. to produce the final product.

English name: Polytetrafluoro ethylene

Specific gravity: 2.1-2.2 grams per cubic centimeter

Forming shrinkage rate: 3.1-7.7%

Forming temperature: 330-380 ℃

Drying conditions:---

Material performance

1. Long term use at temperatures ranging from -200 to 260 degrees Celsius, it has excellent chemical corrosion resistance and is resistant to all chemicals. Its friction coefficient is the lowest among plastics, and it also has excellent electrical properties. Its electrical insulation is not affected by temperature, earning it the title of "plastic king".

2. It is in a transparent or semi transparent state, and the higher the crystallinity, the worse the transparency. The raw materials are mostly powdered resins or concentrated dispersions, which have extremely high molecular weight and are high crystallinity thermoplastic polymers.

Suitable for making corrosion-resistant parts, wear reducing and wear-resistant parts, sealing parts, insulation parts, and medical device parts

Forming performance

1. Crystalline material with low moisture absorption.

2. Poor fluidity, easily decomposes, and produces corrosive gases during decomposition. It is advisable to strictly control the molding temperature, the mold should be heated, and the pouring system should have low resistance to material flow.

3. Powdered resins are often formed using powder metallurgy and sintering methods. The sintering temperature should be between 360 and 380 degrees, and should not exceed 475 degrees. Lotion resin is usually processed by cold extrusion and then sintering, which can form an anti-corrosion coating on the surface of articles. If transparency and good toughness are required for the product, rapid cooling should be adopted. Extrusion molding can also be adopted, which can extrude pipes, rods, and profiles.

4. The viscosity of PTFE melt is very high, and the volume viscosity decreases with the increase of shear stress, indicating its non Newtonian fluid characteristics.

5. Secondary processing can include hot pressing composite, welding, bonding, reinforcement, mechanical processing, etc. to produce the final product.

-

- What is the material of polytetrafluoroethylene

2023-12-09

-

- The characteristics of polytetrafluoroethylene high-temperature cloth

2023-12-09

-

- Application field of polytetrafluoroethylene

2023-12-09

-

- PTFE polytetrafluoroethylene

2023-12-09

-

- PTFE Staple Fiber

- Key features:

• 100% PTFE white resin materials

• Excellent high and low temperature performance:-196°C~260°C

• Excellent chemical resistance • Low shrinkage • Humidity resistance • Ageing resistance • LOI:95%

-

- PTFE Filament Yarn

- Key features:

• 100% PTFE white resin materials

• Excellent high and low temperature performance:-196°C~260°C

• Excellent chemical resistance • High tensile strength • Low shrinkage • Humidity resistance • Ageing resistance • LOI:95%

-

- PTFE Sewing Thread

- Key features:

• 100% PTFE white resin materials

• Excellent high and low temperature performance:-196℃~260℃

• Excellent chemical resistance • High tensile strength • Low shrinkage • Humidity resistance • Ageing resistance • LOI:95%

-

- PTFE Scrim

- PTFE scrim is made from our PTFE filament yarn,which can be used as scrim of high temperature needle felt,the dust filter bag will be broken because of weak aging resistance of PPS and glass fiber scrim,PTFE scrim as substitute of traditional scrim has increased the life of the needle when acupunctured with PPS,P84,NOMEX fiber (Specifc can be customized according to customer needs).

闽ICP备2024028878号

闽ICP备2024028878号