News

Category

What is the material of polytetrafluoroethylene

Publish:2023-12-09 14:33:42

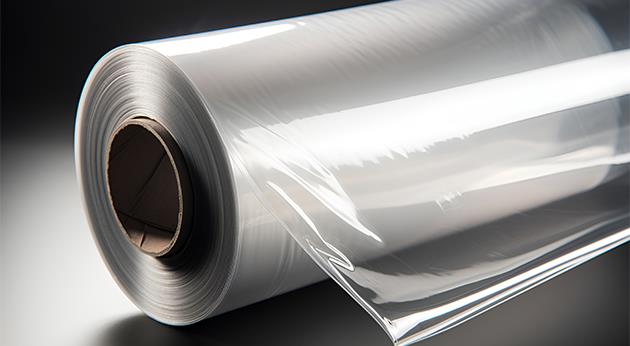

Polytetrafluoroethylene (PTFE), commonly known as "plastic", is a high molecular weight polymer synthesized by polymerization of tetrafluoroethylene as a monomer. It is a white waxy semi transparent resin with excellent properties such as heat resistance, cold resistance, corrosion resistance, electrical insulation, non stick properties, and low friction coefficient, making it widely used in various fields.

The molecular structure of polytetrafluoroethylene is a perfluorocarbon group, which makes it highly chemically stable. It can resist almost all chemical substances, including strong acids, strong bases, strong oxidants, etc., and is not prone to chemical reactions even at high temperatures. Therefore, polytetrafluoroethylene is widely used in anti-corrosion equipment and pipelines in industries such as chemical, petroleum, pharmaceutical, food, and textile.

Another important feature of polytetrafluoroethylene is its non adhesive properties. Due to its unique molecular structure, the surface of polytetrafluoroethylene has extremely low surface tension, so it will not adhere to any substances, including water and oil. This makes polytetrafluoroethylene widely used in the production of non stick pots, bearings, sealing rings, and other aspects.

In addition, polytetrafluoroethylene also has good electrical insulation performance. Its dielectric constant is extremely low, so it can maintain good insulation performance even under high voltage. This makes polytetrafluoroethylene have important applications in the production of wires, cables, electronic components, and other fields.

Polytetrafluoroethylene also has good mechanical properties. It has high hardness, tensile strength, and compressive strength, so it has good wear resistance and impact resistance. This makes polytetrafluoroethylene widely used in the production of wear-resistant components such as bearings, gears, and skateboards.

However, polytetrafluoroethylene also has some drawbacks. Firstly, its processing difficulty is high, requiring special processing equipment and technology. Secondly, its high cost limits its application in some fields., Polytetrafluoroethylene can decompose into toxic gases at high temperatures, posing certain risks to the environment.

Overall, polytetrafluoroethylene is a polymer material with superior properties, and it has wide applications in various fields. However, due to its high processing difficulty and cost, as well as the potential generation of harmful substances at high temperatures, we still need to be cautious when using it. Polytetrafluoroethylene (PTFE) is a high molecular weight polymer polymerized from tetrafluoroethylene as a monomer, with the chemical formula (C2F4) n. It is a white waxy semi transparent polymer material with low density and excellent properties such as high and low temperature resistance, corrosion resistance, insulation, low friction coefficient, and self-lubricating. Therefore, it is widely used in various fields.

The molecular structure of polytetrafluoroethylene is characterized by the alternating arrangement of carbon and fluorine atoms, forming highly stable C-F bonds. The binding force of this bond is very strong, making polytetrafluoroethylene highly chemically stable and exhibiting excellent corrosion resistance to almost all chemical substances. At the same time, the number of fluorine atoms in polytetrafluoroethylene molecules is much greater than that of hydrogen atoms, making its surface energy extremely low and less prone to adhesion with other substances. Therefore, polytetrafluoroethylene has good non stick and low friction coefficient.

The high and low temperature resistance of polytetrafluoroethylene is also very excellent. Its glass transition temperature is about 100 ℃, melting point is about 327 ℃, and thermal decomposition temperature is about 410 ℃. Within the temperature range of -190 ℃ and 260 ℃, polytetrafluoroethylene can maintain excellent physical and mechanical properties. In addition, polytetrafluoroethylene also has good electrical insulation and radiation resistance, and can be used to make wires and cables, high-frequency insulation materials, etc.

Due to its excellent properties, polytetrafluoroethylene has been widely used in various fields. In the chemical industry, polytetrafluoroethylene can be used as anti-corrosion coatings, sealing materials, valve fillers, etc; In the field of electronics and electrical appliances, polytetrafluoroethylene can be used as an insulation layer for wires and cables, as well as a packaging material for electronic components; In the aerospace field, polytetrafluoroethylene can be used as a sealing material for rocket engines and thermal protective coatings for spacecraft; In the field of medical devices, polytetrafluoroethylene can be used as a manufacturing material for implants such as artificial joints and heart valves; In the field of construction, polytetrafluoroethylene can be used as roof waterproofing material, external wall insulation material, etc.

However, polytetrafluoroethylene also has some drawbacks. Firstly, its processing difficulty is high, requiring special processing techniques to produce the desired shape and size; Secondly, the high price of polytetrafluoroethylene increases production costs; Later, polytetrafluoroethylene will decompose at high temperatures to produce toxic gases, which pose certain hazards to the environment.

In summary, polytetrafluoroethylene is a polymer material with superior properties, widely used in various fields. Although it has some drawbacks, with the development of science and technology, these problems are expected to be solved. The future application prospects of polytetrafluoroethylene are still very broad.

The molecular structure of polytetrafluoroethylene is a perfluorocarbon group, which makes it highly chemically stable. It can resist almost all chemical substances, including strong acids, strong bases, strong oxidants, etc., and is not prone to chemical reactions even at high temperatures. Therefore, polytetrafluoroethylene is widely used in anti-corrosion equipment and pipelines in industries such as chemical, petroleum, pharmaceutical, food, and textile.

Another important feature of polytetrafluoroethylene is its non adhesive properties. Due to its unique molecular structure, the surface of polytetrafluoroethylene has extremely low surface tension, so it will not adhere to any substances, including water and oil. This makes polytetrafluoroethylene widely used in the production of non stick pots, bearings, sealing rings, and other aspects.

In addition, polytetrafluoroethylene also has good electrical insulation performance. Its dielectric constant is extremely low, so it can maintain good insulation performance even under high voltage. This makes polytetrafluoroethylene have important applications in the production of wires, cables, electronic components, and other fields.

Polytetrafluoroethylene also has good mechanical properties. It has high hardness, tensile strength, and compressive strength, so it has good wear resistance and impact resistance. This makes polytetrafluoroethylene widely used in the production of wear-resistant components such as bearings, gears, and skateboards.

However, polytetrafluoroethylene also has some drawbacks. Firstly, its processing difficulty is high, requiring special processing equipment and technology. Secondly, its high cost limits its application in some fields., Polytetrafluoroethylene can decompose into toxic gases at high temperatures, posing certain risks to the environment.

Overall, polytetrafluoroethylene is a polymer material with superior properties, and it has wide applications in various fields. However, due to its high processing difficulty and cost, as well as the potential generation of harmful substances at high temperatures, we still need to be cautious when using it. Polytetrafluoroethylene (PTFE) is a high molecular weight polymer polymerized from tetrafluoroethylene as a monomer, with the chemical formula (C2F4) n. It is a white waxy semi transparent polymer material with low density and excellent properties such as high and low temperature resistance, corrosion resistance, insulation, low friction coefficient, and self-lubricating. Therefore, it is widely used in various fields.

The molecular structure of polytetrafluoroethylene is characterized by the alternating arrangement of carbon and fluorine atoms, forming highly stable C-F bonds. The binding force of this bond is very strong, making polytetrafluoroethylene highly chemically stable and exhibiting excellent corrosion resistance to almost all chemical substances. At the same time, the number of fluorine atoms in polytetrafluoroethylene molecules is much greater than that of hydrogen atoms, making its surface energy extremely low and less prone to adhesion with other substances. Therefore, polytetrafluoroethylene has good non stick and low friction coefficient.

The high and low temperature resistance of polytetrafluoroethylene is also very excellent. Its glass transition temperature is about 100 ℃, melting point is about 327 ℃, and thermal decomposition temperature is about 410 ℃. Within the temperature range of -190 ℃ and 260 ℃, polytetrafluoroethylene can maintain excellent physical and mechanical properties. In addition, polytetrafluoroethylene also has good electrical insulation and radiation resistance, and can be used to make wires and cables, high-frequency insulation materials, etc.

Due to its excellent properties, polytetrafluoroethylene has been widely used in various fields. In the chemical industry, polytetrafluoroethylene can be used as anti-corrosion coatings, sealing materials, valve fillers, etc; In the field of electronics and electrical appliances, polytetrafluoroethylene can be used as an insulation layer for wires and cables, as well as a packaging material for electronic components; In the aerospace field, polytetrafluoroethylene can be used as a sealing material for rocket engines and thermal protective coatings for spacecraft; In the field of medical devices, polytetrafluoroethylene can be used as a manufacturing material for implants such as artificial joints and heart valves; In the field of construction, polytetrafluoroethylene can be used as roof waterproofing material, external wall insulation material, etc.

However, polytetrafluoroethylene also has some drawbacks. Firstly, its processing difficulty is high, requiring special processing techniques to produce the desired shape and size; Secondly, the high price of polytetrafluoroethylene increases production costs; Later, polytetrafluoroethylene will decompose at high temperatures to produce toxic gases, which pose certain hazards to the environment.

In summary, polytetrafluoroethylene is a polymer material with superior properties, widely used in various fields. Although it has some drawbacks, with the development of science and technology, these problems are expected to be solved. The future application prospects of polytetrafluoroethylene are still very broad.

-

- What is the material of polytetrafluoroethylene

2023-12-09

-

- The characteristics of polytetrafluoroethylene high-temperature cloth

2023-12-09

-

- Application field of polytetrafluoroethylene

2023-12-09

-

- PTFE polytetrafluoroethylene

2023-12-09

-

- PTFE Staple Fiber

- Key features:

• 100% PTFE white resin materials

• Excellent high and low temperature performance:-196°C~260°C

• Excellent chemical resistance • Low shrinkage • Humidity resistance • Ageing resistance • LOI:95%

-

- PTFE Filament Yarn

- Key features:

• 100% PTFE white resin materials

• Excellent high and low temperature performance:-196°C~260°C

• Excellent chemical resistance • High tensile strength • Low shrinkage • Humidity resistance • Ageing resistance • LOI:95%

-

- PTFE Sewing Thread

- Key features:

• 100% PTFE white resin materials

• Excellent high and low temperature performance:-196℃~260℃

• Excellent chemical resistance • High tensile strength • Low shrinkage • Humidity resistance • Ageing resistance • LOI:95%

-

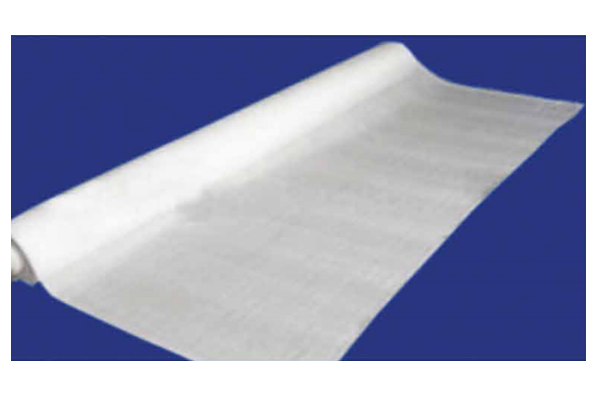

- PTFE Scrim

- PTFE scrim is made from our PTFE filament yarn,which can be used as scrim of high temperature needle felt,the dust filter bag will be broken because of weak aging resistance of PPS and glass fiber scrim,PTFE scrim as substitute of traditional scrim has increased the life of the needle when acupunctured with PPS,P84,NOMEX fiber (Specifc can be customized according to customer needs).

闽ICP备2024028878号

闽ICP备2024028878号